End-amino polyether D-400

End-amino polyether D-400

Keyword:

Category:

Polyurea raw materials

Hotline:

Email:

End-amino polyether D-400

Product Name Terminal Aminopolyether

Model Number D-400

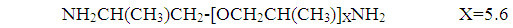

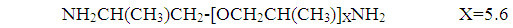

Chemical Structure

Overview

D-400 is a diamine based on a copolymer backbone. The average molecular weight is approximately 400, and its amino group is located on the second carbon atom at the end of the polyether. D-400 has a density of 0.91 g/cm³ at 25℃, a flash point of 190℃, a melting point of -28℃, a pH of 11.6, and a boiling point of 250℃; D-400 has an active equivalent weight of 115, is characterized by its light color, low viscosity, low vapor pressure, and high primary amine content; it is soluble in many solvents and slightly soluble in water.

Physicochemical Indicators

Application

D-400 is a novel epoxy curing agent. It can be used to produce tough, clear, elastic, and compression-resistant coatings, castings, and adhesives. In any case, combining D-400 with other curing agents helps increase the elasticity of the product. The manufacture of epoxy products using D-400 not only exhibits high elasticity but also features no shrinkage, low curing temperature, and low heat distortion temperature. D-400 can be used in protective and decorative epoxy coatings, paving materials including non-elastic floors, and crack fillers. D-400 can be used for reinforcement of low-viscosity epoxy products and for the repair of compounds and the protection of corroded wood. The combination of D-400 with high-molecular-weight D-2000 produces epoxy products with high peel strength. As a non-epoxy application, D-400 is used as an active chain extender in polyurethane RIM (Reaction Injection Molding). It can also be used in thermoplastic polyurethane adhesives and in the cutting of salts and liquids, fire retardants, etc.

Safety and Toxicity

D-400 can potentially cause severe burns to the skin and eyes, and can cause poisoning through skin absorption and ingestion. When handling this product, wear goggles with a face shield and impermeable gloves; when handling large spills, wear impermeable clothing and rubber boots. In case of contact, thoroughly flush eyes with water for at least 15 minutes and seek immediate medical attention. If skin contact occurs, immediately wash the exposed area with soap and plenty of water.

Packaging, Storage, and Transportation

D-400 is usually packaged in 200 kg nitrogen-filled iron drums. Store in a dark, cool, and dry place. Shelf life is one year.

Model Number D-400

Chemical Structure

Overview

D-400 is a diamine based on a copolymer backbone. The average molecular weight is approximately 400, and its amino group is located on the second carbon atom at the end of the polyether. D-400 has a density of 0.91 g/cm³ at 25℃, a flash point of 190℃, a melting point of -28℃, a pH of 11.6, and a boiling point of 250℃; D-400 has an active equivalent weight of 115, is characterized by its light color, low viscosity, low vapor pressure, and high primary amine content; it is soluble in many solvents and slightly soluble in water.

Physicochemical Indicators

| Color Number Pt-Co | ≤100 |

| Primary Amine Content % | ≥97 |

| Amine Value mmol/g | 4.10-4.70 |

| Water Content % | ≤0.25 |

D-400 is a novel epoxy curing agent. It can be used to produce tough, clear, elastic, and compression-resistant coatings, castings, and adhesives. In any case, combining D-400 with other curing agents helps increase the elasticity of the product. The manufacture of epoxy products using D-400 not only exhibits high elasticity but also features no shrinkage, low curing temperature, and low heat distortion temperature. D-400 can be used in protective and decorative epoxy coatings, paving materials including non-elastic floors, and crack fillers. D-400 can be used for reinforcement of low-viscosity epoxy products and for the repair of compounds and the protection of corroded wood. The combination of D-400 with high-molecular-weight D-2000 produces epoxy products with high peel strength. As a non-epoxy application, D-400 is used as an active chain extender in polyurethane RIM (Reaction Injection Molding). It can also be used in thermoplastic polyurethane adhesives and in the cutting of salts and liquids, fire retardants, etc.

Safety and Toxicity

D-400 can potentially cause severe burns to the skin and eyes, and can cause poisoning through skin absorption and ingestion. When handling this product, wear goggles with a face shield and impermeable gloves; when handling large spills, wear impermeable clothing and rubber boots. In case of contact, thoroughly flush eyes with water for at least 15 minutes and seek immediate medical attention. If skin contact occurs, immediately wash the exposed area with soap and plenty of water.

Packaging, Storage, and Transportation

D-400 is usually packaged in 200 kg nitrogen-filled iron drums. Store in a dark, cool, and dry place. Shelf life is one year.

Related Products

Online Message

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.